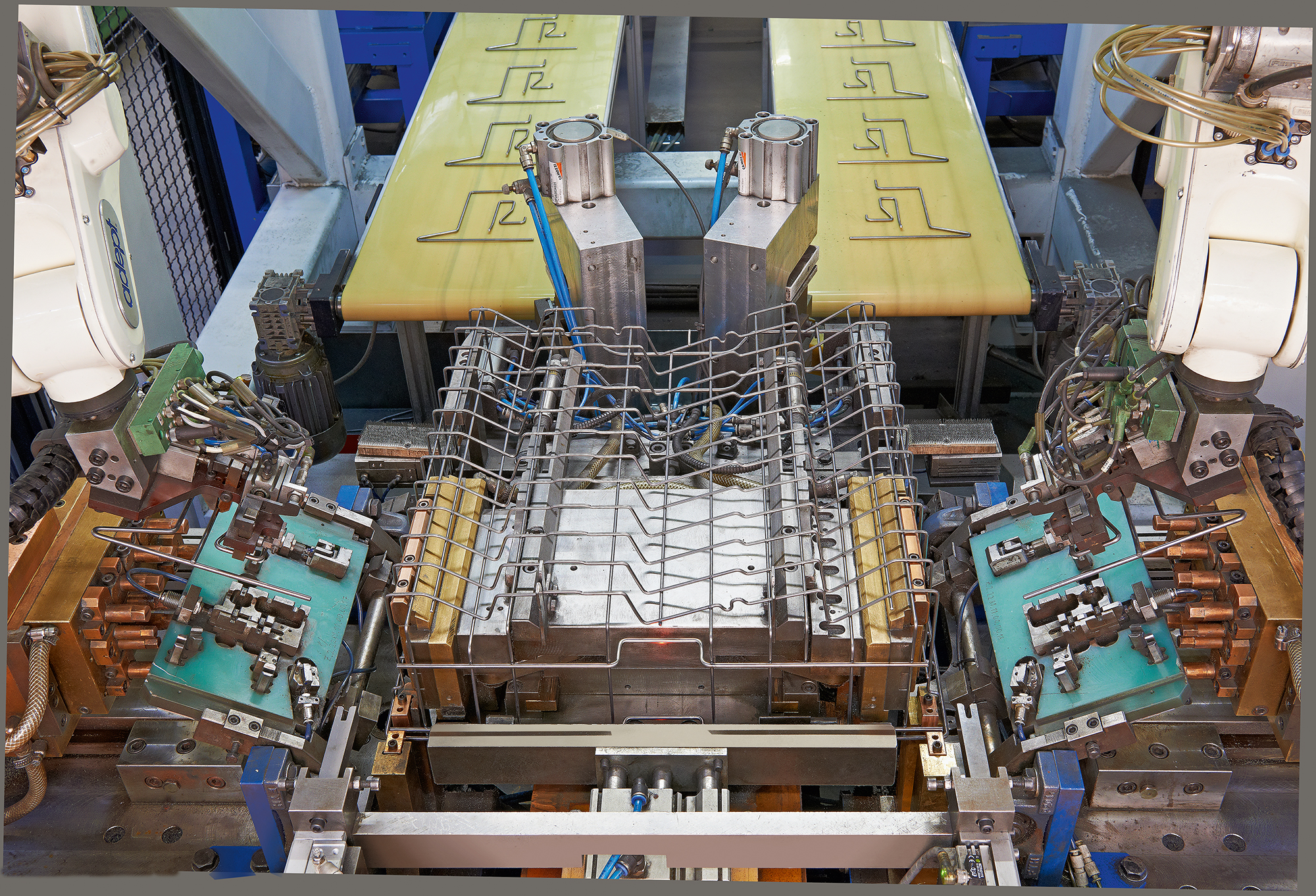

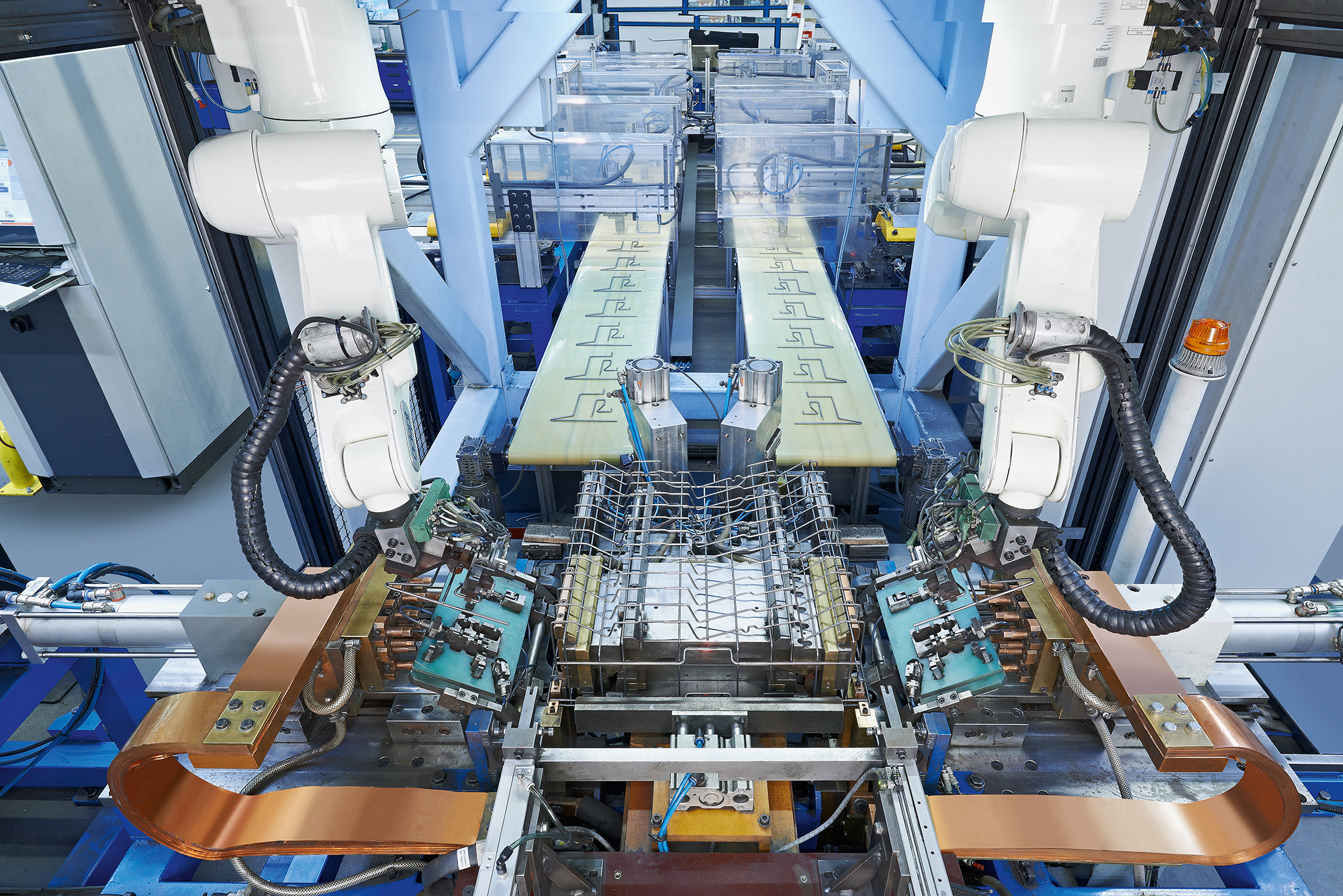

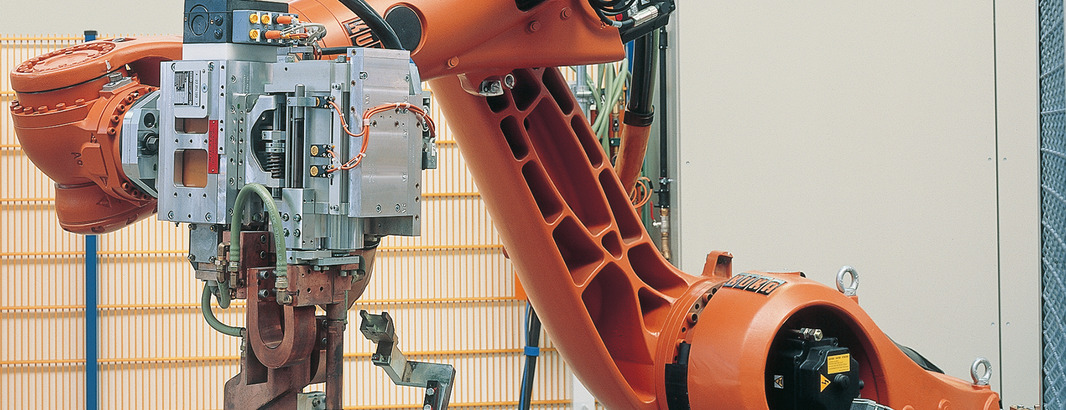

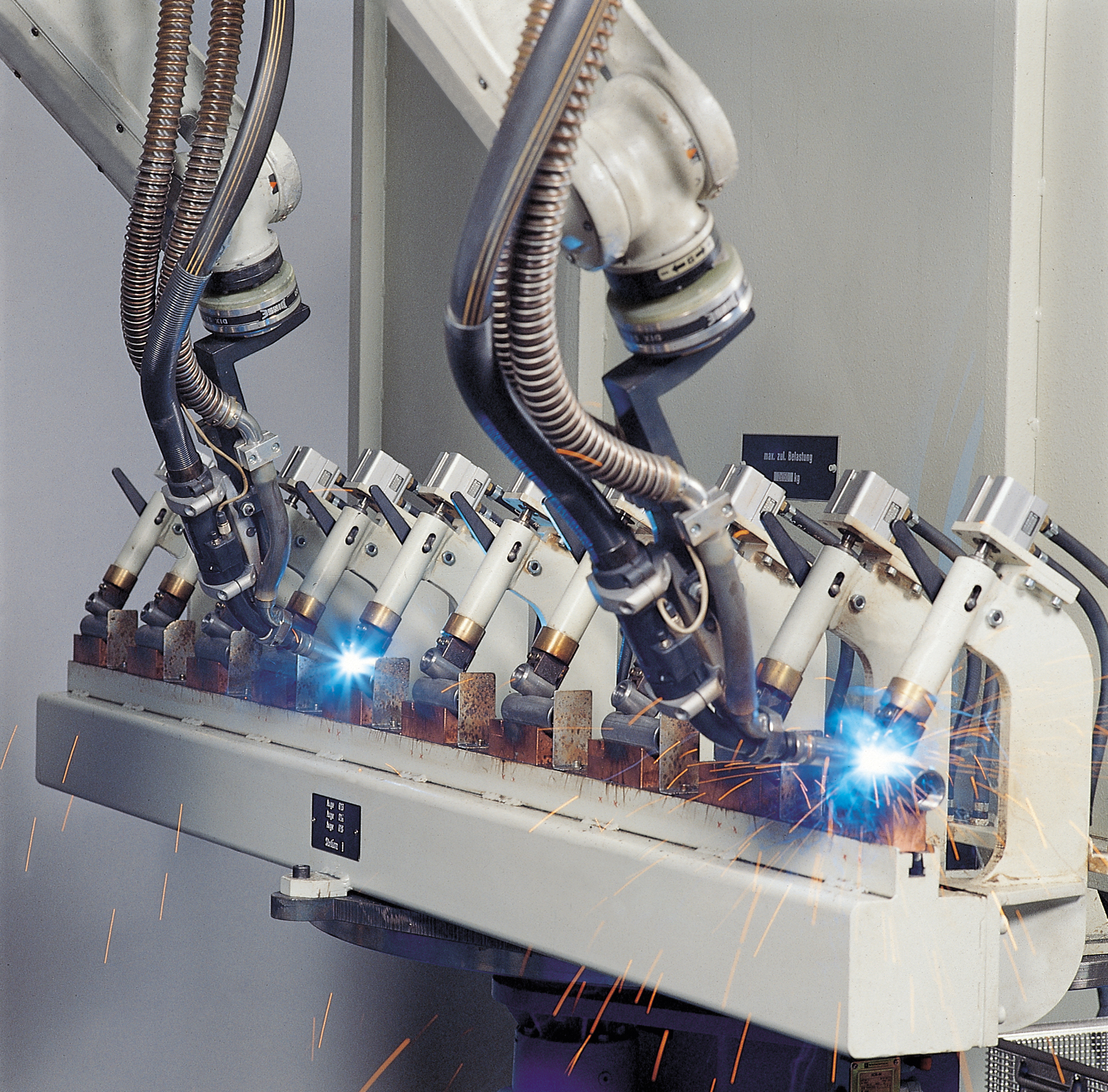

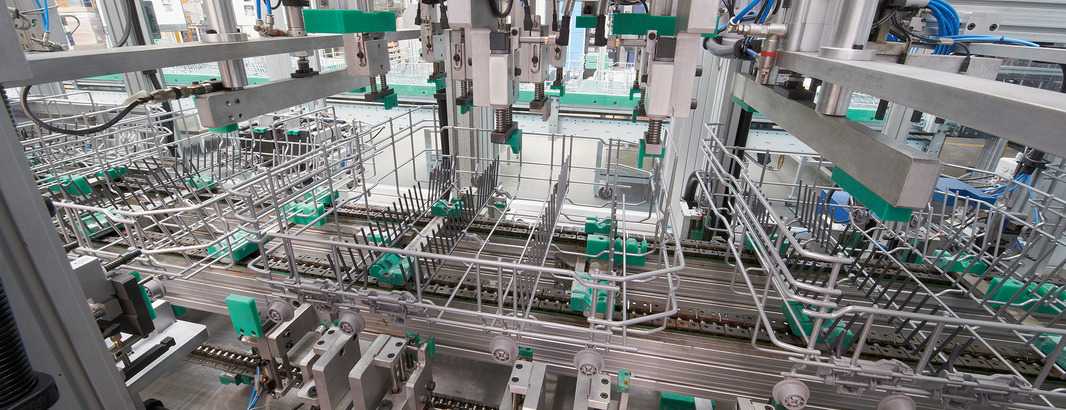

Tool production

Manpower and technology for tools, devices and special machinery. The company's construction of its own tools for welding and forming tools ensures availability and quick response times. Construction of our own tools and devices is needed to turn ideas into products quickly.

- Quick responses to customer requests

- Flexible implementation of new projects

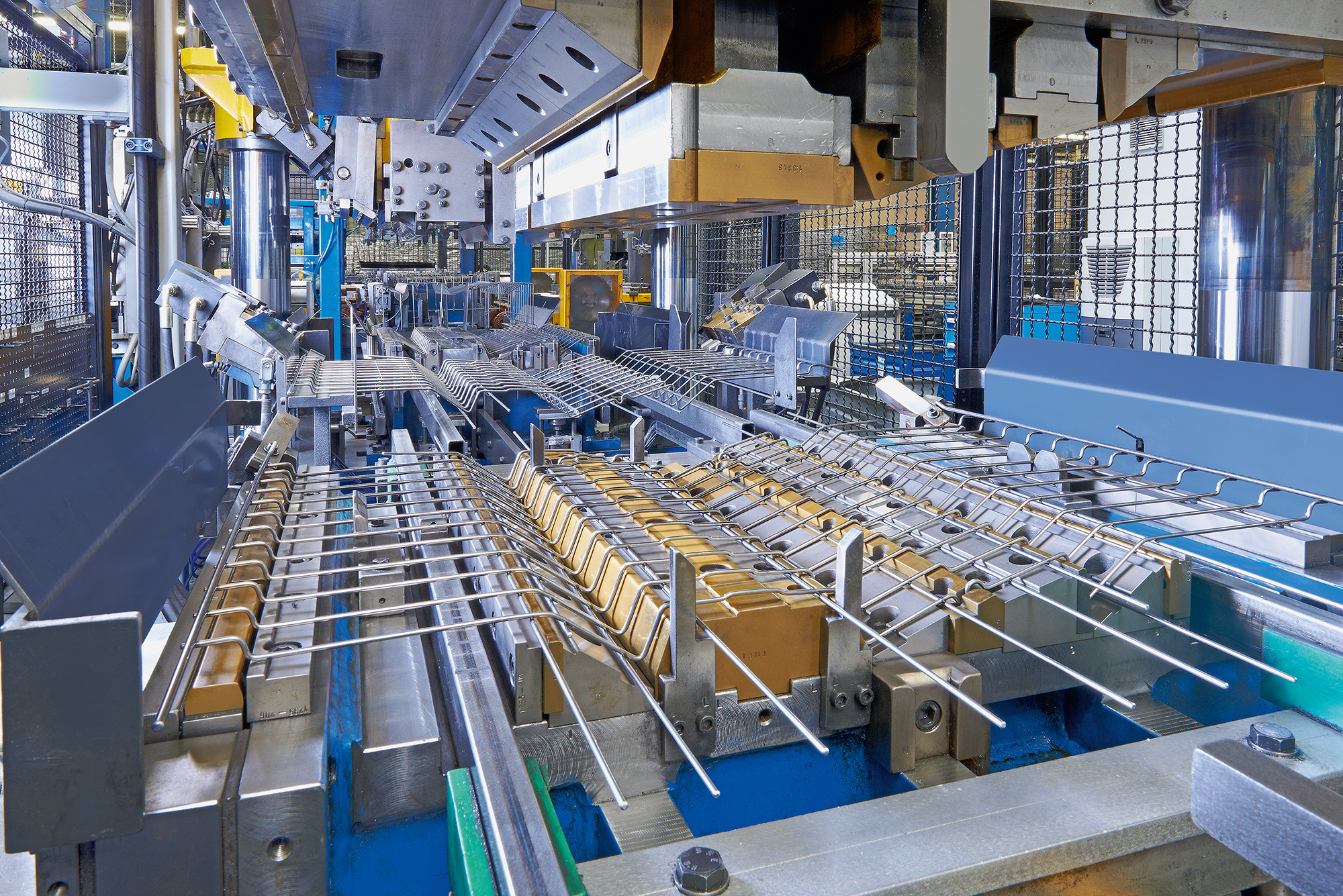

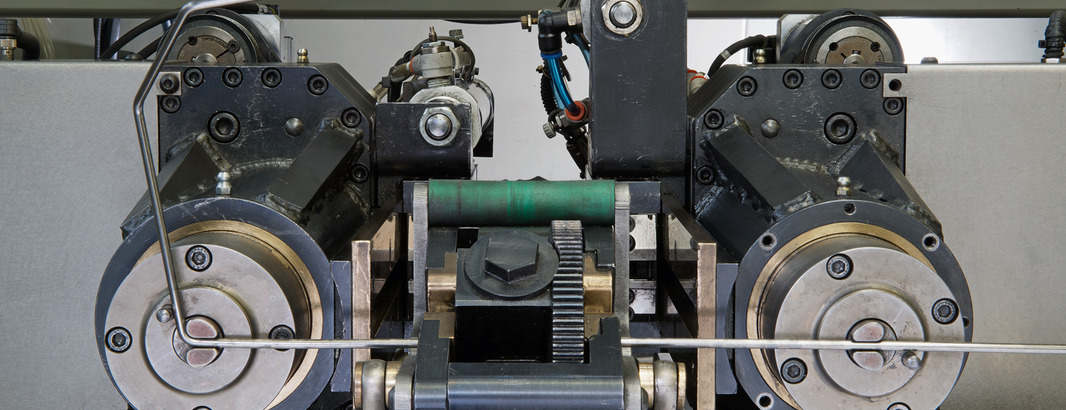

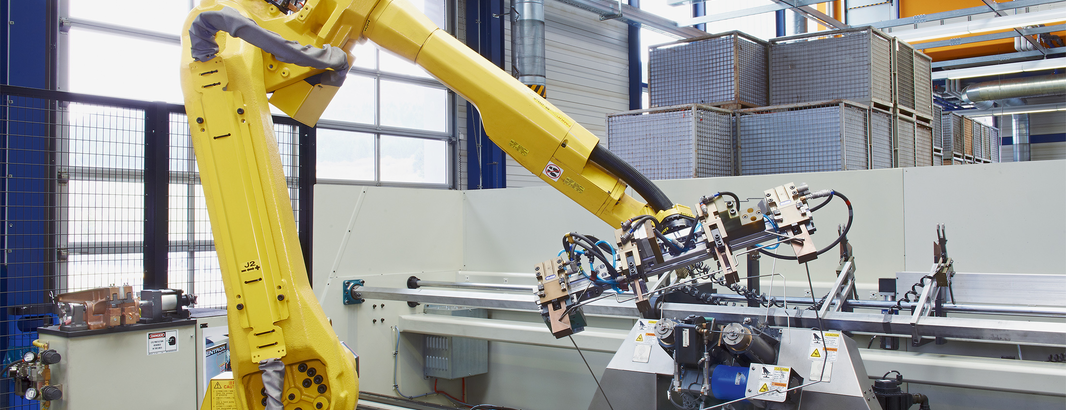

Bending

Our modern machine park, with CNC-controlled 3D bending machines, highly qualified employees and decades of experience, ensures that your wire product idea becomes a marketable, technically well-developed and series-optimized product - in any batch size, even as an individual component in 3D bending technology. We can bend just about anything - give us a try.

Surface refinement

Corrosion protection and damage protection, identification and tactile concerns are some of the aspects that need to be taken into consideration when choosing the right surface refinement. We use the fluidised bed coating process to obtain a high-quality polyamide coating on wire products with a wire diameter of up to 14 mm.

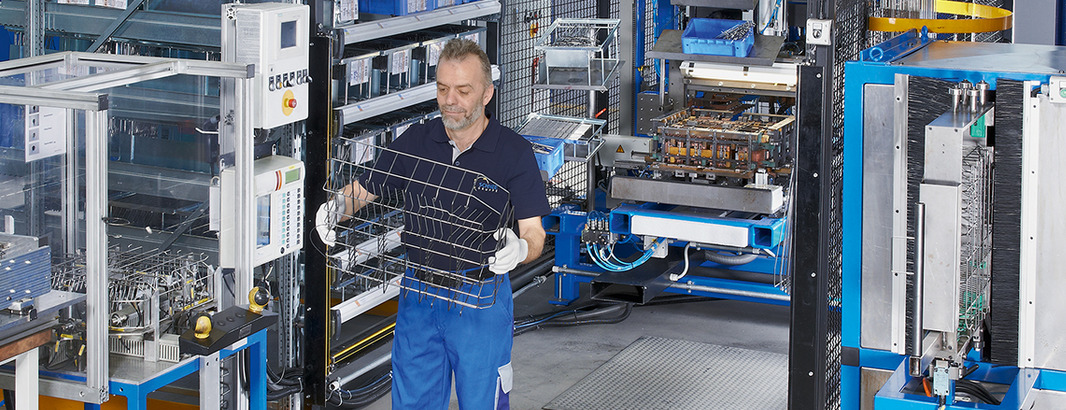

Logistic

We have developed economical and environmentally friendly packaging that protects our products optimally and which can be partially reused. We also organize the logistics - with selected forwarding companies and our own fleet of vehicles - so that your Schnee-Gruppe products will be delivered to your production lines at the right time.